FPT Industrial, alongside its brand Potenza Technology, has announced the achievement of ISO 26262 ASIL C certification from TÜV SÜD for its in-house developed eBM 5 Battery Management System (BMS) for high voltage batteries. This certification reaffirms the company’s strong commitment to technological innovation and continuously improving the safety of its products for customers.

Key Milestone in Electrification Roadmap

Pierpaolo Biffali, Vice President Product Engineering at FPT Industrial, commented: “This is an important step forwards in consolidating our electrification roadmap to accelerate decarbonization of the commercial vehicles segment. Each technological innovation we make always translates into tangible value for our customers, and the eBM 5 represents a solid way to ensure the efficient and safe operation of their battery electric vehicles.“

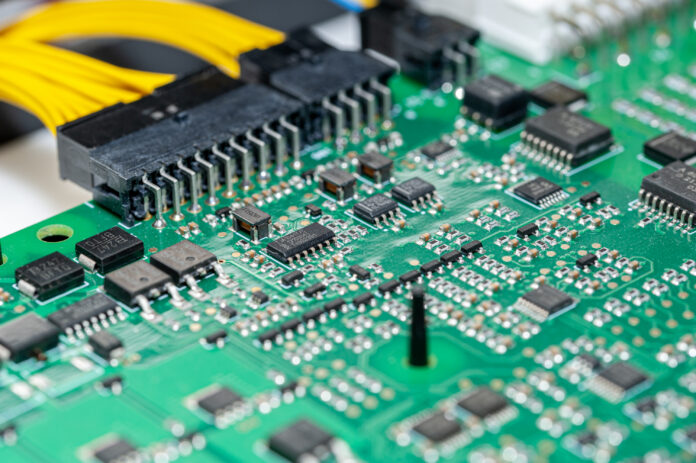

Fifth-Generation BMS: Flexible and Scalable

The integrated FPT Industrial and Potenza Technology team entirely designed and developed the fifth-generation battery management system, eBM 5, in-house. This includes the circuitry, the software base, and the application layers. This state-of-the-art system offers flexibility and scalability. Its highly modular design is compatible with 400V or 800V battery systems. Consequently, OEMs can configure these systems at an application level. This optimizes vehicle efficiency and performance. Furthermore, this enables OEMs to maximize the system’s effectiveness for each use case across the mobility spectrum – from commercial vehicles to hypercars – including multi-pack management (which is not in scope of the certification) without an additional controller. The IVECO eDaily MY24 and numerous other customers currently use the eBM 5 in volume production.

Focus on Robustness, Reliability, and Safety

Neeta Khare, Battery and Fuel Cell Director at FPT Industrial, commented: “Throughout the development phase, the team was driven by the principle of making our product robust, reliable, and safe. As a result, we implemented significant improvements across various areas, including processes, testing infrastructure, design documentation, and traceability – from requirements to testing. This enhanced approach has led to the TÜV SÜD ASIL C certification and has also further strengthened our confidence in the reliability and safety of our BMS product.”

External Certification Ensures Quality

Richard Devenport, General Manager & Head of Battery Development at Potenza Technology, an FPT Industrial brand, stated: “This is a true achievement that has been years in the making. The goal was always to produce an OEM standard Battery Management System suitable for a wide range of vehicles. While other BMS suppliers often use the ‘self-certification’ process, where their work products are reviewed within their own company to confirm compliance to the standard, we aimed to have ours assessed by an external body, to guarantee a level of quality and completeness that few others can boast. We backed up that claim by going the extra mile to obtain certification from TÜV SÜD, one of the world’s leading experts on functional safety and a founding participant in the establishment of the ISO 26262 standard.”

Understanding ISO 26262 ASIL C

ISO 26262 is an international standard for functional safety in the automotive industry. It applies to electrical and electronic systems that consist of hardware and software components in vehicles. This standard defines the requirements for both the safety-relevant functions of the system and the development process. This ensures that an adequate level of safety is maintained throughout the vehicle lifecycle. Moreover, the standard relies on ASIL (Automotive Safety Integrity Level). ASIL is a risk classification system that analyzes potential hazards by considering the severity, frequency, and controllability of the vehicle’s operational scenarios.

eBM 5 – Technical Specifications:

- High Voltage range: 400 V and 800 V systems

- Low Voltage range: 6 to 32 V

- Operating Temperature (C°): -40 to 85

- Software – Multipack Support: Yes (not in scope of the certification)

- ASIL System: ASIL C

- Algorithm (SOX): inbuilt

Complete specifications are available on FPT Industrial’s website.